WWTP

for hotels and guest houses

For owners of boarding houses and hotels, we will solve the worries of wastewater from consulting, project and selection phase to the installation and subsequent service of the treatment plant. We are an experienced and a serious partner with our own Czech production. Become a member of our qualified sales and service team and offer ENVI-PUR products in your country.

Introduction of WWTP for guesthouses and hotels

For wastewater treatment in hotels and boarding houses, a container wastewater treatment plant is the best choice. The treatment plant works on the principle of an aerobic cleaning process, so when functioning correctly, there are unnecessary fears of odour. Container treatment plants also respect the requirement for the lowest possible noise. We will help you choose the size and model of the container treatment plant with regard to the capacity of the guests, seasonal and off-season operation and, last but not least, to your individual requirements concerning the region, legislation or selection of accessories. In the case of a smaller boarding house (up to 30 EO), a circular domestic WWTP for cottages may be a suitable choice. The BC biocleaner WWTP is certified according to ČSN EN 12566-3-A1

Models of ENVI-PUR WWTPs

| BC biocleaner BC OPTIMA | BC 16 | BC 20 | BC 25 | BC 30 | |

| Number of people connected | [PE] | 16 | 20 | 25 | 30 |

| Amount of waste water Q24 | [m³/day] | 2,4 | 3,0 | 3,8 | 4,5 |

| Electric input when loaded | [W] | 280 | 550 | 1 100 | 1 100 |

| Maximal energy demand | [kWh/day] | 6,7 | 13,2 | 26,4 | 26,4 |

|

Weight: Container; Circle |

[kg] | 600 [310] | 800 [370] | 1200 [490] | 1 800 |

Control unit: Control unit with the possibility of setting 10 programs and with the possibility of manually triggered removal of floating dirt.

The set contains: Plastic tank of WWTP, technological installation, membrane blower, control unit OPTIMA.

| BC biocleaner BC COMFORT | BC 16 | BC 20 | BC 25 | BC 30 | BC 40 | |

| Number of people connected | [PE] | 16 | 20 | 25 | 30 | 40 |

| Amount of waste water Q24 | [m³/day] | 2,4 | 3,0 | 3,8 | 4,5 | 6,0 |

| Electric input when loaded | [W] | 280 | 550 | 1 100 | 1 100 | 1 100 |

| Maximal energy demand | [kWh/day] | 6,7 | 13,2 | 26,4 | 26,4 | 26,4 |

|

Weight: Container;[circle] |

[kg] | 600 [310] | 800 [370] | 1200 [490] | 1 800 | 1 800 |

| BC 50 | BC 100 | BC 150 | BC 200 | ||

| Number of people connected | [PE] | 50 | 100 | 150 | 200 |

| Amount of waste water Q24 | [m³/day] | 7,5 | 15,0 | 22,5 | 30 |

| Electric input when loaded | [W] | 1 500 | 1 500 | 1 500 | 1 500 |

| Maximal energy demand | [kWh/day] | 36,0 | 36,0 | 36,0 | 36.0 |

|

Weight: Container |

[kg] | 2 400 | 2 500 | 3 000 | 4 500 |

- Control unit: Comfort+ control unit with advanced control options

- The set contains: Plastic WWTP tank, technological installation, membran blower, Comfort+ control unit

| BC biocleaner | BC 16 | BC 20 | BC 25 | BC 30 | BC 40 | |

| Number of people connected | [PE] | 16 | 20 | 25 | 30 | 40 |

| Amount of waste water Q24 | [m³/day] | 2,4 | 3,0 | 3,8 | 4,5 | 6,0 |

| Electric input when loaded | [W] | 280 | 550 | 1 100 | 1 100 | 1 100 |

| Maximal energy demand | [kWh/day] | 6,7 | 13,2 | 26,4 | 26,4 | 26,4 |

|

Weight: Container;[circle]] |

[kg] | 600 [310] | 800 [370] | 1200 [490] | 1 800 | 1 800 |

| BC 50 | BC 100 | BC 150 | BC 200 | ||

| Number of people connected | [EO] | 50 | 100 | 150 | 200 |

| Amount of waste water Q24 | [m³/day] | 7,5 | 15,0 | 22,5 | 30 |

| Electric input when loaded | [W] | 1 500 | 1 500 | 1 500 | 1 500 |

| Maximal energy demand | [kWh/day] | 36,0 | 36,0 | 36,0 | 36.0 |

|

Weight: Container |

[kg] | 2 400 | 2 500 | 3 000 | 4 500 |

-

- Control unit: Comfort+ control unit with advanced control options

- The set contains: Plastic WWTP tank, technological installation, membran blower, Comfort+ control unit

The treatment plant model can be extended with a UV lamp on the drain - BC EXCLUSIVE UV

Technical specifications of WWTP

| BASIC | OPTIMA | COMFORT | EXCLUSIVE | |

| Tank for concrete encasement | ||||

| Self supported tank | ||||

| Concrete tank | ||||

| Control system OPTIMA with 10 pre-programmed modes | ||||

| Programmable control system Comfort+ | ||||

| Automatic cleaning levels settlement tank | ||||

| Lowering settlement tank | ||||

| Integrated tertiary filter | ||||

| UV disinfection | ||||

| Aerators replaceable in operation | ||||

| Oxygen / pH probe | ||||

| Possibility of GSM connection |

Accessories can be ordered for the WWTPs

Advantages of ENVI-PUR WWTPs

-

Lifetime period

Our WWTPs are made of high quality material with an extremely long durability. The quality of processing of every treatment plant is very important to us.

-

You will not know about the WWTP

The WWTPs work reliably independently in a continuous process and, thanks to smart functions, they are able to easily change operation, eg to a weekend mode. The noise level does not exceed the Db of a standard refrigerator.

-

Saving water

The use of a treatment plant is one of the prerequisites for modern ecological living and lifestyle. The toilets can be flushed or watered with cleaned water.

-

Lower related costs

The costs invested in the treatment plant will pay you back in about a year, compared to the outdated use of sumps. It is an investment for a stable and reliable wastewater treatment solution.

Manufacturer ENVI-PUR, s.r.o.

The cornerstones of our portfolio are wastewater treatment plants, water treatment plants, rainwater tanks and recycling. Our focus and acquired knowledge and skills from these fields complement each other perfectly. This is our major benefit for quality of expertise, experience and know-how of our non-transferability, which we gained from the very beginning

Quality of material

We produce only from primoplastic - we do not use recycled plastic. We use high-quality certified plastics from the Röchling company, which guarantee the required mechanical properties of the plastic tank. The mechanical properties of the water tank are proven by static calculation, the wall thickness of the tank is 8 mm (does not apply to the BASIC model - 6 mm).

Production and quality

The development, production, storage and dispatch of wastewater treatment plants takes place in Soběslav, South Bohemia. Our "brains" are our technologists and engineers who work closely with scientific institutions and universities. Our installers are thoroughly trained. We check suppliers and monitor quality. We are proud to be an exclusively Czech company. We meet the standards and regulations valid in the Czech Republic and the European Union. The treatment plants are certified according to ČSN12566-3 + A2 and meet the requirements of the call for municipalities No. 17/2017.

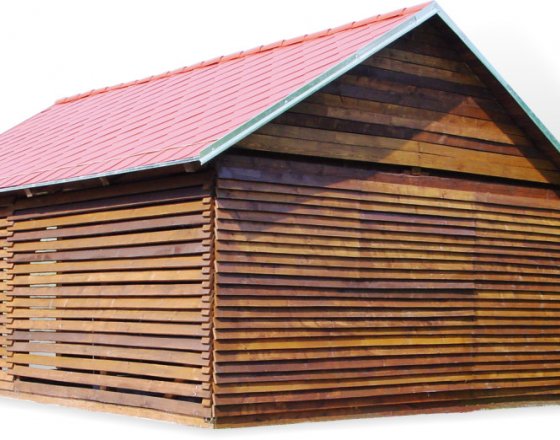

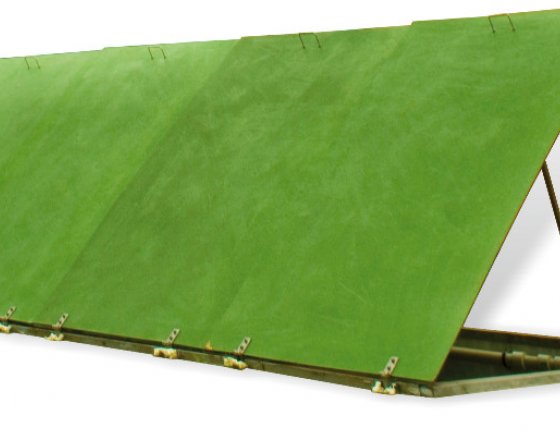

Pictures from the production

How to install a domestic wastewater treatment plant

We will be happy to help you

If you have any questions, our experts will help you immediately.