Microbubble flotation MiFlo

effective, austerity, compact

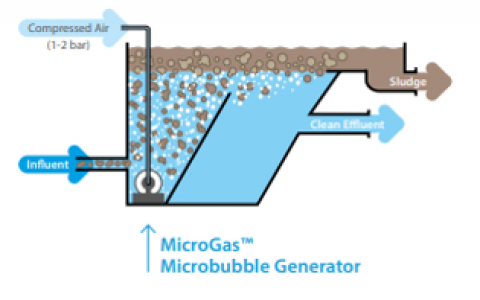

Microbubble flotation is a separation process based on bringing contaminants to the surface by microbubbles of air.

The MiFlo plant is designed primarily for the treatment of industrial wastewater.

Air microbubbles are directly created in the water by rotating ceramic MicroGas™ membrane discs. This is the main difference from dissolved air flotation (DAF), where the air is dissolved in water using high pressure.

The membrane discs create so-called white water in the contact zone, a mixture of water and air microbubbles, that carry contaminants to the surface in the contact zone and then in the separation zone. At the end of the separation zone, the cleaned water is pumped out from the bottom and the floating layer of dirt is mechanically removed from the surface.

Key Features

-

Low power consumption.

-

Compact technology.

-

Long service life.

-

Easy installation, operation and maintenance.

-

Fast technology start-up after shutdown.

-

Allows for reconstructions and/or intensification of existing technology.

Advantages over DAF

-

Absence of water recycling, recirculation pump and saturator.

-

Smaller footprint area.

-

Lower operating pressure (1-2 bar).

-

Up to 90% energy savings.

-

Also suitable for applications with limited gas solubility (elevated temperature or water salinity)

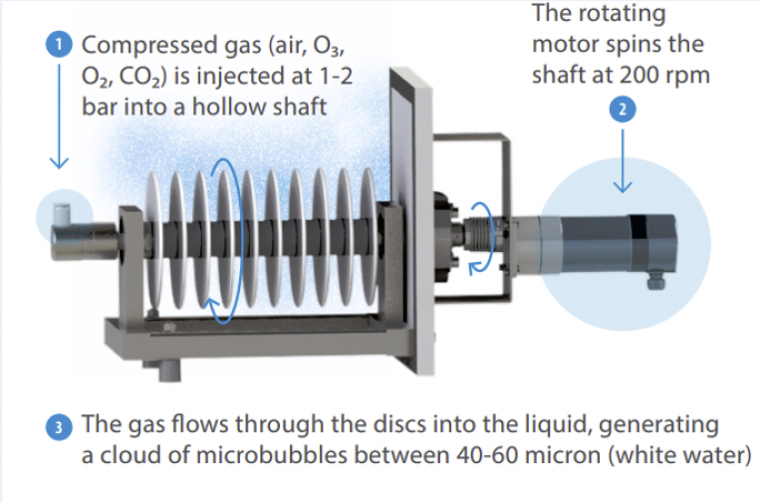

The basis of MiFlo is a microbubble generator, which consists of a series of rotating ceramic membrane disks.

Compressed gas is injected into the generator under pressure (1-2 bar) and the rotating ceramic membrane disks create bubbles of 40-60 microns size.